In today’s competitive manufacturing landscape, precision is more important than ever. When components need to fit perfectly and perform flawlessly, you can’t afford to cut corners. That’s where precision CNC machining comes in. RADMOT, with 40 years of experience, stands as a leader in this field, offering high-quality precision CNC machining services tailored to meet the most demanding industry standards. Our commitment to accuracy, combined with state-of-the-art machinery and a skilled workforce, allows us to produce intricate parts with extreme precision, helping businesses across various industries achieve their goals.

What is Precision CNC Machining?

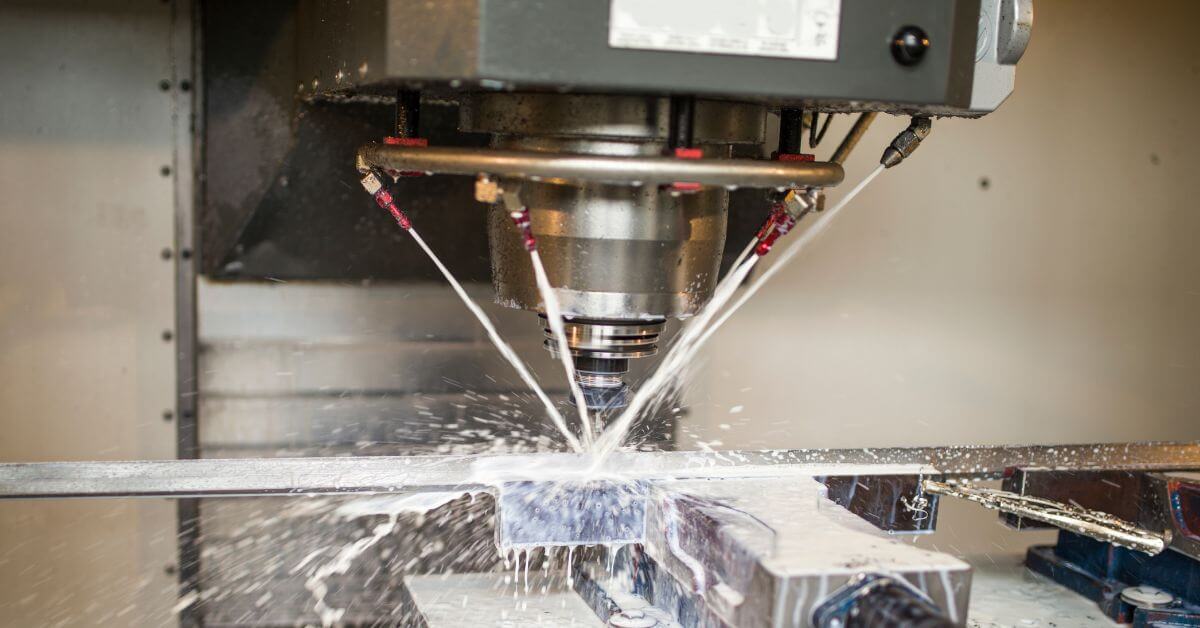

Precision CNC machining is the process of using advanced Computer Numerical Control (CNC) machines to manufacture components with exceptional accuracy. CNC technology allows us to control tools and machines via computer programs, ensuring that parts are manufactured with consistent precision, regardless of complexity. At RADMOT, our machines are capable of working with tolerances as tight as a few microns, which is critical for industries such as aerospace, medical, and automotive, where even the slightest deviation from design specifications can lead to failure.

Precision machining involves multiple techniques, including milling, turning, drilling, and grinding. With multi-axis CNC machines, RADMOT can produce highly complex geometries in a single setup, reducing errors, improving efficiency, and speeding up production times. This level of precision is not just about creating parts that fit; it’s about ensuring that every component functions flawlessly within its system, helping to improve the performance and reliability of the final product.

The Importance of Precision in CNC Machining

In sectors like aerospace, defense, and medical, precision isn’t just a preference—it’s a necessity. Whether you’re manufacturing critical engine components, medical implants, or parts for heavy industrial equipment, the success of your product depends on its precision. Inaccurate parts can lead to system failures, increased wear and tear, or even safety hazards. That’s why industries with high-performance demands turn to CNC machining for their manufacturing needs.

At RADMOT, we understand the importance of precision in CNC machining. Our advanced CNC machines, combined with rigorous quality control protocols, ensure that every part we produce meets exact specifications. This level of accuracy is achieved through the use of cutting-edge software, sophisticated measurement tools like CMMs (Coordinate Measuring Machines), and decades of experience in fine-tuning our processes to deliver reliable results.

One of the biggest benefits of precision CNC machining is the ability to manufacture complex parts in large quantities without sacrificing quality. Our CNC machines are programmed to repeat the same process over and over again with incredible accuracy, meaning you can count on consistent results, even in high-volume production runs. This repeatability reduces the likelihood of defects and ensures that every part you receive is identical to the one before it, saving time and resources in assembly and testing.

Why Choose RADMOT for Precision CNC Machining?

RADMOT’s precision CNC machining services are built around a foundation of quality, efficiency, and expertise. With four decades in the industry, we have honed our skills and invested in the latest CNC technology to offer our clients the best possible outcomes. Our CNC machining plant is equipped with multi-axis machines capable of handling even the most complex designs, and our team of 200 skilled professionals works tirelessly to ensure that every part we produce meets or exceeds client expectations.

We work with a wide range of materials, including aluminum, stainless steel, titanium, and engineering plastics. Each material has its own characteristics, and our team is well-versed in optimizing the machining process to get the best results, whether we’re working with soft metals or hard alloys. Our expertise extends beyond simply cutting parts to include material selection, tool optimization, and surface finishing, ensuring that the final product is ready for use.

Precision doesn’t stop at machining; it carries through to our commitment to customer service. At RADMOT, we believe in clear communication and transparency at every step of the process. From the initial consultation to the delivery of finished parts, we keep you informed, providing regular updates and working closely with you to ensure that your requirements are met. Our focus on client collaboration allows us to offer customized solutions that are tailored to your specific needs, whether you’re looking for one-off prototypes or full production runs.